👃 Why Scent Retention Matters

In the candle business, fragrance is the primary selling point. Customers often decide within seconds based on the cold throw (scent when unlit). If a candle loses its fragrance during storage or shipping, it undercuts the product’s value and risks damaging your brand reputation.

That’s why scent retention—ensuring fragrance oils stay locked inside the candle until use—is one of the most critical considerations in vessel and lid design.

🛡️ Role of Lids in Fragrance Protection

A high-quality lid does far more than act as a dust cover:

-

Preserves Fragrance: Prevents scent molecules from dissipating.

-

Improves Shelf Life: Keeps products fresh longer during storage.

-

Adds Premium Appeal: Metal, wood, or marble lids elevate perceived value.

Standardized lid programs through Candle jar wholesale ensure compatibility with common jar sizes, reducing procurement headaches.

🧩 Liners & Inner Seals

Some premium candles incorporate liners or sealing elements:

-

Foam or Rubber Liners: Create an airtight closure when the lid is applied.

-

Heat-Sealed Foil: Locks fragrance until the consumer peels it away.

-

Plastic Snap Caps: Useful for mass-market candles that ship long distances.

These solutions not only extend shelf life but also reduce fragrance cross-contamination when different candles are stored in close proximity.

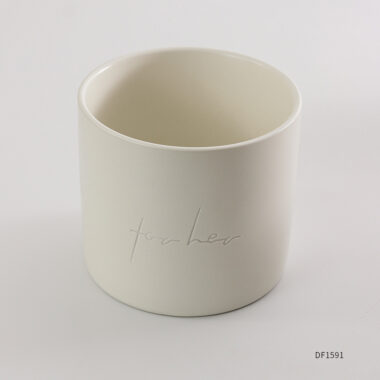

🏺 Jar Geometry & Fit Tolerances

The jar itself affects sealing performance:

-

Straight-Sided Jars: Allow consistent lid fit across batches.

-

Beveled Edges: Add elegance but require more precise lid tooling.

-

Ceramic Jars: Shrinkage during firing may create tolerance variation, making seal testing essential.

For premium projects, many buyers partner with Candle Tins Manufacturer, where tins naturally provide tighter closures and better portability.

📦 Storage & Shipping Considerations

Even with quality lids and seals, poor storage can still compromise scent:

-

Heat & Sunlight: Accelerate fragrance evaporation.

-

Temperature Fluctuations: Cause wax expansion and contraction, breaking seals.

-

Long Transit Times: Require stronger closures to withstand months in shipping containers.

Warehouses should maintain stable, cool environments, and packaging should minimize direct sunlight exposure.

🧪 Testing Scent Retention

Factories and brands should conduct controlled testing before mass production:

-

Weight Loss Tracking: Measuring evaporation rates of wax samples with lids over time.

-

Sensory Panels: Human testers compare cold throw intensity after 30, 60, and 90 days.

-

Seal Integrity Tests: Simulating transportation stress to check if lids remain secure.

This ensures that by the time products reach consumers, they deliver the intended fragrance experience.

🌍 Market Preferences in Lids & Seals

-

North America: Metal lids with foam liners dominate premium retail.

-

Europe: Wooden lids and sustainable cork options align with eco-conscious buyers.

-

Asia-Pacific: Decorative lids (gold, silver, embossed) serve both practical and gifting purposes.

Tailoring lid and seal solutions to regional consumer expectations improves product acceptance and market success.

✅ Final Takeaway

Scent retention is about more than wax formulation—it’s about integrated vessel, lid, and seal design. By investing in high-quality closures and proper storage practices, brands can guarantee consistent cold throw, longer shelf life, and a premium unboxing experience.

In competitive markets, the fragrance is your promise to the customer. Make sure it lasts.