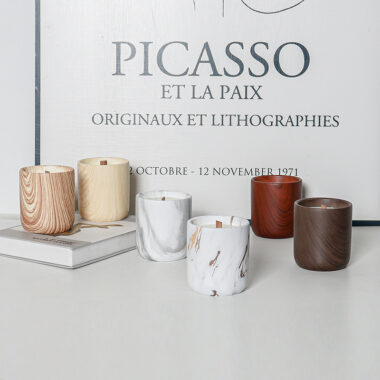

🎨 Why Decoration Matters

A candle’s fragrance and performance are critical, but visual presentation drives the first purchase. In competitive retail spaces, decoration methods like printing, decals, and hot stamping elevate candle jars from simple containers to brand-defining assets. For B2B buyers, investing in the right decoration increases perceived value and market differentiation.

🖌️ Screen Printing for Bold Branding

Screen printing is the most common method for applying logos, text, and simple graphics onto glass or ceramic candle jars.

-

Advantages: Durable, cost-effective, ideal for large-volume orders.

-

Limitations: Limited color range per design, best for bold, simple logos.

-

Best Use Case: Mass retail lines requiring consistency across thousands of units.

Factories supplying through Candle jar wholesale often provide standard screen printing as part of their decoration services.

🏷️ Decals for Complex Designs

Decals allow full-color, detailed graphics that screen printing cannot achieve. They are printed on transfer paper and applied to the jar surface before firing.

-

Advantages: High-resolution, multi-color artwork with gradients.

-

Limitations: Slightly higher cost, more complex application process.

-

Best Use Case: Seasonal collections or limited-edition designs requiring more artistry.

For buyers wanting premium artistry, a Glass Candle Jar Manufacturer ensures consistency in decal application across clear or frosted vessels.

✨ Hot Stamping for Luxury Effects

Hot stamping uses metallic foils pressed onto the jar surface with heat and pressure, creating reflective, shiny effects.

-

Advantages: Metallic finishes (gold, silver, rose gold) convey luxury.

-

Limitations: Higher tooling cost and setup time, better for mid- to high-volume orders.

-

Best Use Case: Luxury SKUs positioned for gifting and premium retail.

Hot stamping is often combined with frosted or tinted glass to create striking contrast.

🔄 Combination Techniques

The most eye-catching designs often combine methods:

-

Screen print + hot stamping = bold logo plus luxury accent.

-

Decals + soft-touch coating = tactile and visual premium appeal.

-

Engraving + hot stamping = long-lasting design with reflective highlights.

These hybrid approaches are gaining popularity among high-end candle brands seeking differentiation.

📦 Durability Testing of Decoration

Decoration must withstand handling, shipping, and consumer use. Tests include:

-

Adhesion Tests: Checking if prints withstand rubbing or scratching.

-

Heat Tests: Ensuring metallic foils or decals don’t degrade under candle burn temperatures.

-

Dishwasher Resistance: For jars designed to be reused post-candle.

Durability is a critical factor in reducing product returns and complaints.

🧮 MOQ and Cost Considerations

-

Screen Printing: MOQs as low as 1,000 pcs.

-

Decals: Typically require 2,000–3,000 pcs minimum.

-

Hot Stamping: Starts at 3,000 pcs, due to tooling setup costs.

For brands testing new markets, screen printing offers low entry barriers, while hot stamping works best for established luxury lines.

✅ Final Takeaway

Decoration turns candle jars into brand ambassadors. Whether it’s a bold printed logo for retail chains, an intricate decal for seasonal collections, or shimmering hot stamping for luxury lines, choosing the right method ensures your candles not only smell good but also sell well.

By partnering with reliable factories offering multiple decoration techniques, brands can scale from entry-level to luxury SKUs without compromising consistency.